Metis Engineering, a leading specialist in battery sensor technology, has addressed the unsustainable and unnecessary scrapping of used EVs as a result of the automotive market not having sufficient access to vehicle battery health data.

- Used, healthy EVs being needlessly scrapped if involved in minor collisions

- Until now there has been no way to inform consumers or insurers on the condition of a used EV, causing a major barrier to a thriving second-hand market

- Metis Engineering’s Cell Guard is a unique sensor with an accelerometer capable of measuring Shock load and duration up to +/-24G

- Vital information provides much needed transparency data on battery health

- Benefits include more sustainable ecosystem for EVS, as well as improved re-sale value of EVs and can help reduce high insurance premiums

- Cell Guard can also monitor VOCs, Pressure change, Humidity, Water ingress and Dew point, of lithium-ion battery packs, detecting cell venting and early warning of thermal runaway within seconds

- Tested and certified to ISO Automotive Standards

At the mobility event, Metis Engineering highlighted how the lack of transparent data on electric vehicle battery health, which is unable to help inform consumers, dealers or insurers of the state of the battery condition, is leading to EVs being needlessly scrapped if they are involved in the most minor collisions.

Until now, the used EV market has not had an effective method to provide consumers with clear data on the health of a car’s battery. Consequently, insurance companies face uncertainty when assessing potential battery damage, often resulting in conservative write-offs even if they have travelled only a few miles. This practice not only raises insurance premiums for consumers but also contributes to unnecessary waste, hindering the circular economy principles that underpin the EV industry.

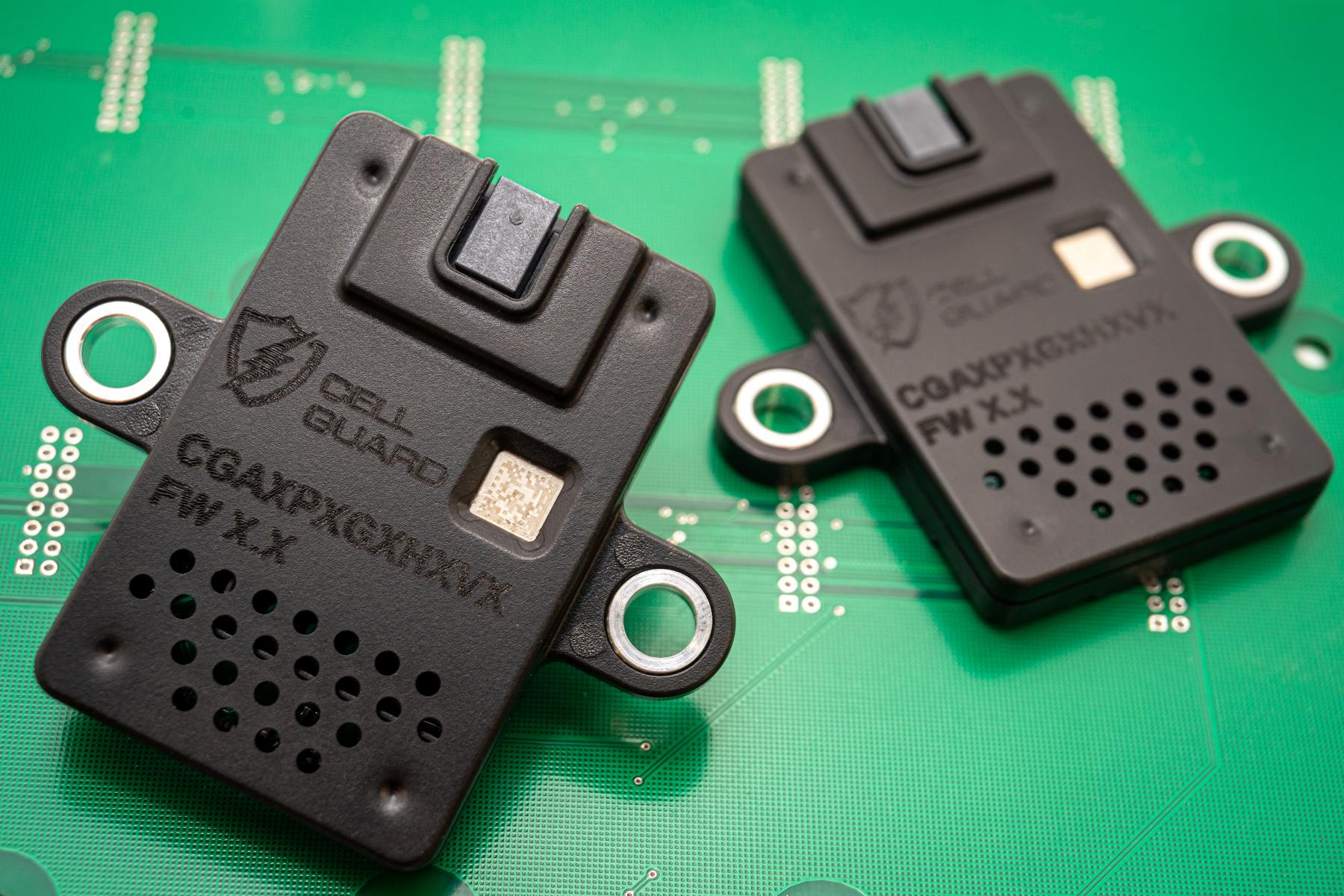

Cell Guard from Metis Engineering has been developed to solve this problem. Its first-to-market innovative solution is a CAN based sensor that can be easily integrated into almost any battery system and features an accelerometer to measure Shock load and duration up to +/-24G.

The matchbox-sized unit is a unique sensor that provides unrivalled accurate and detailed information on the health of a lithium-ion battery pack by relaying any Shock data over a configurable CAN interface to a control unit, such as the vehicle’s ECU, which can be accessed to provide far greater insight into the battery’s condition for repurposing and recycling, as well as any subsequent insurance claims.

This information can radicalise the re-sale market of used EVs, with buyers given much needed clarity to be able to make informed decisions regarding battery pack condition, as well as its maintenance.

Joe Holdsworth, CEO, Metis Engineering said: “The unknown risk of poor EV battery health is one of the biggest and most significant barriers hindering the growth of the used electric vehicle market. By providing consumers and insurers unprecedented insights into battery health, it empowers informed decision-making while minimising uncertainty surrounding minor collision damage. Cell Guard is game-changing solution that bridges the gap between insurers, consumers, and the EV industry.

Developed using ISO26262 processes and certified to ISO Automotive Standards, Cell Guard is manufactured in the UK under strict quality-controlled conditions to satisfy orders from a rapidly growing number of OEMs and Tier 1s where they are being used in ASIL B applications

Cell Guard is also capable of detecting cell venting, which is an early sign of catastrophic battery failure vastly reducing the risk of thermal runaway. Unlike current battery cell monitoring systems (BMS), which typically only offer temperature and voltage sensors, Cell Guard monitors a range of environmental parameters required to ensure that the battery continues to operate in optimum conditions, including VOCs, Pressure change, Humidity, and Dew point.

With Cell Guard, Metis Engineering is setting a new standard for advanced battery health monitoring in EVs and Energy Storage Systems

Metis Engineering

Metis Engineering Ltd is based in Bristol, United Kingdom. The company has produced a range of innovative sensors for the automotive industry. These include:

Cell Guard, for the EV battery pack health monitoring and the early detection of thermal runaway of lithium-ion battery packs.

Inertial Measurement Unit (IMU) – a CAN-based sensor which monitors 3 axis of acceleration, rotation, quaternion angles and pitch, roll and yaw.

Untethered Dead Reckoning (UDR) – a standalone CAN-based sensor that outputs latitude, longitude, altitude and Corse Over Ground. Ideal for when GPS / GNSS signal is lost.

Air Quality – a CAN-based sensor that measures gaseous parameters to determine cabin HVAC system operation.

Metis Engineering’s sensors are in use in a wide range of applications including: Bloodhound LSR, Brompton Bicycles, high-performance electric aircraft, motorsport: Formula E and World Rally Championship, Energy Storage Systems and autonomous vehicles

Be the first to comment